In the current industrial scenario, innovation and sustainability are key elements to remain competitive. 3DRap presents itself as a strategic partner for companies that wish to evolve the production method, while offering eco-friendly and sustainable solutions. This dossier illustrates how 3DRap, thanks to the use of recyclable materials and advanced additive manufacturing technologies, can support companies in the transition towards a greener and more profitable future.

Time Optimization and Cost Reduction

Elimination of High Fixed Costs

3DRap additive manufacturing eliminates the need for expensive molds and tooling, significantly reducing fixed costs. This flexible approach allows you to produce components on demand, avoiding the accumulation of unused inventory and optimizing the use of resources.

3DRap additive manufacturing eliminates the need for expensive molds and tooling, significantly reducing fixed costs. This flexible approach allows you to produce components on demand, avoiding the accumulation of unused inventory and optimizing the use of resources.

Acceleration of the Development Cycle

Thanks to 3D printer technology, 3DRap is able to bring ideas from concept to reality in record time. This allows companies to quickly test production batches and make changes along the way, significantly reducing product development and market launch times.

Eco-sustainable Solutions and Recyclable Materials

Use of Biodegradable Materials

3DRap uses PLA (polylactic acid), a bioplastic derived from renewable resources such as corn starch. This material not only reduces environmental impact, but also helps create a sustainable product life cycle, essential for companies committed to the green transition.

Production of rubbers and elastomers

3DRap is capable of printing a wide range of rubbers and elastomers, reaching variable degrees of hardness thanks to the sectorial and selective filling capacity offered by 3D printing production technology. This allows us to create customized products for specific mechanical and functional needs.

Use of ESD Conductive Polymers

Among the materials treated by 3DRap there are also ESD (Electro Static Discharge) conductive polymers, which allow the safe storage and transport of sensitive electronic components. These materials, 100% recyclable and free of added fibers, offer safe and environmentally friendly solutions for companies in the electronics sector.

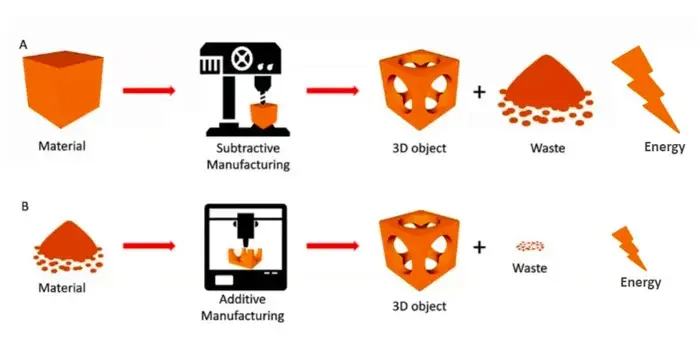

Reduction of Waste

The additive manufacturing process used by 3DRap produces significantly less waste than traditional manufacturing methods. Thanks to the precision and flexibility of 3D printing, it is possible to optimize the quantity of material used, ensuring that the mechanical and functional characteristics of the objects remain unchanged.

Flexibility and Adaptability of the Production Process

Editable projects in progress

One of the main advantages of additive manufacturing is the possibility of varying designs during production without having to remake the molds. This allows for tremendous flexibility, allowing companies to quickly adapt to market needs and continuously improve their products.

One of the main advantages of additive manufacturing is the possibility of varying designs during production without having to remake the molds. This allows for tremendous flexibility, allowing companies to quickly adapt to market needs and continuously improve their products.

Regeneration of Existing Structures

3DRap offers the possibility of replacing modular pieces for products already in use, allowing companies to recover and regenerate existing structures. This approach not only extends the useful life of products, but also reduces the need for new resources, further contributing to environmental sustainability.

Automation and Artificial Intelligence

Autonomy and Low Environmental Impact

3DRap 3D printers are almost completely autonomous machines, with low environmental impact and low energy consumption. They do not require major maintenance and can be managed in large numbers by a single operator, even remotely, thanks to integration with advanced monitoring and control systems.

3DRap 3D printers are almost completely autonomous machines, with low environmental impact and low energy consumption. They do not require major maintenance and can be managed in large numbers by a single operator, even remotely, thanks to integration with advanced monitoring and control systems.

Advanced Optimization with AI and Machine Learning

3DRap implements the use of Artificial Intelligence and Machine Learning in its operations. These technologies allow the machines to continuously adapt and optimize themselves to the working environment, improving the quality, mechanical resistance and lead times of the pieces produced. This level of advanced optimization guarantees maximum efficiency and reliability in production.

Ready for the Green Transition

Commitment to Sustainability

3DRap is already aligned with global sustainability goals, offering solutions that meet the needs of companies engaged in the transition to a circular economy. Our technology and our recyclable materials represent a step forward towards the creation of a greener future, where production efficiency is combined with respect for the environment.

3DRap is already aligned with global sustainability goals, offering solutions that meet the needs of companies engaged in the transition to a circular economy. Our technology and our recyclable materials represent a step forward towards the creation of a greener future, where production efficiency is combined with respect for the environment.

Energy saving

3DRap’s strong commitment to environmental sustainability is also highlighted through the use of a photovoltaic system that covers the company’s entire energy needs. This approach further reduces the environmental impact of production, making 3DRap an ideal partner for companies aiming to reduce their ecological footprint.

3DRap’s strong commitment to environmental sustainability is also highlighted through the use of a photovoltaic system that covers the company’s entire energy needs. This approach further reduces the environmental impact of production, making 3DRap an ideal partner for companies aiming to reduce their ecological footprint.

Conclusion

3DRap represents a cutting-edge solution for companies looking to optimize their manufacturing processes, reduce costs and embrace a sustainable future. Thanks to our innovative technology, the use of recyclable materials and the flexibility of the additive process, we are ready to support businesses in the green transition, helping to build a more sustainable world for future generations.

Contact us to find out how 3DRap can transform your business into an example of sustainability and innovation.